Reducing the Risk of Chainsaw Kickback

Timber Gadgets is reader-supported. We may earn a commission if you buy through the links on our site.

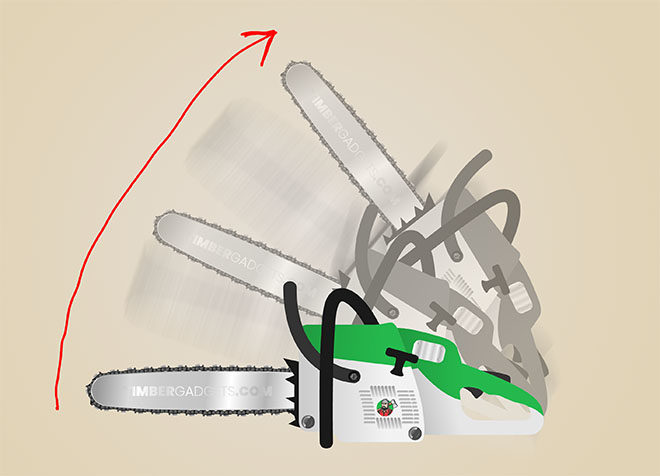

Chainsaw kickback is when the chainsaw bar is thrown upward in an ark-like motion towards the user’s face. This can occur due to many factors, but typically, it happens from one of two things.

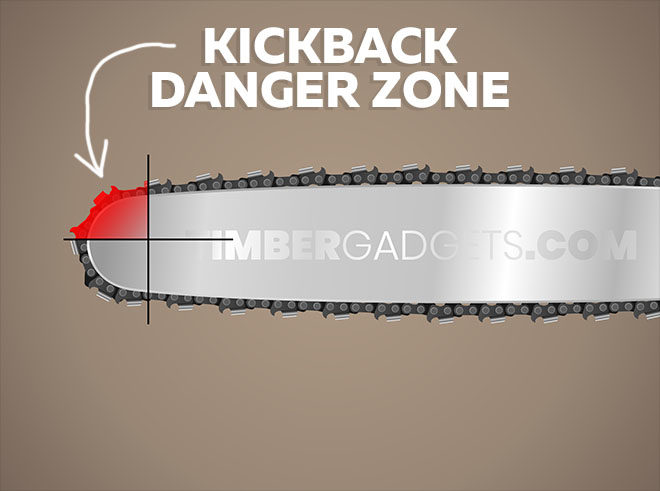

One, the chain catches the wood instead of cutting through it. Due to the direction in which the chain is traveling, it causes the nose of the chainsaw to be thrown upward. When the chain catches the wood, it usually happens near the front of the bar (also known as the nose – please see the “kickback danger zone” picture below).

The second way is if the chain gets pinched in the middle of the cut. Both situations can result in a violent “kick” or “kickback” of the chainsaw.

I shouldn’t have to explain why a moving chainsaw headed towards your upper body or face is problematic; it can result in serious injury or death.

For this reason, it’s important to pay close attention to your surrounding while running a chainsaw. Frequently, it isn’t the branch you’re cutting that causes kickback but rather another tree branch behind it that you don’t see.

You should always wear the proper safety equipment and know that kickback can happen with any chainsaw. Just being aware of your surroundings and knowing that kickback can occur is a good way to stay alert and be cautious.

Table of Contents

How to Reduce The Risk of Chainsaw Kickback

While it’s probably impossible to completely avoid chainsaw kickback, there are some measures you can take to reduce the chance of it. In this section, I’ll review some simple steps to reduce the risk. Also, I’ll give you more information about the chain brake, bumper spikes, and low-kickback chains. The most obvious things are what I’ll go over first.

- Be aware of your surroundings, especially when working around tree branches.

- Read the operating instructions of your chainsaw.

- Wear the appropriate safety equipment.

- Ensure the chain brake works before cutting any wood.

- Pay attention to how the nose of your chainsaw is positioned.

- Have a firm grip on the handles at all times.

I consider the list above to be a fairly standard list of safety precautions. Your chainsaw needs to be maintained and in good working order.

There are three parts of the chainsaw that help to deal with kickback. The first is the “Chain brake” or “Hand Guard.” It’s supposed to shut down the chainsaw if a kickback occurs.

Then there are low-kickback chains; they’re designed to reduce the chances of kickback. Also, “bumper spikes” or “buck spikes” help reduce the chance of kickback while bucking.

Related:

Chain Brake / Hand Guard

The chain brake is typically located in front of the front hand guard and directly above the bar. It is designed to stop the chain if a kickback occurs.

This is one of the most important safety features of a chainsaw. Never remove the chain brake! It’s very important to test the chain brake before you start cutting wood.

Depending on the type of chainsaw you’re using, the actual chain brake mechanism may be located within the motor or in the side cover/panel.

From what I understand, this is how the chain brake works; it’s a metal band that, when activated, clamps down on the clutch drum. By stopping the clutch drum, it stops the sprocket from turning, which stops the chain.

Your wrist or forearm is what activates the chain brake. During a kickback scenario, the chainsaw’s bar is kicked upward; the chain brake/hand guard hits your forearm and stops the chain from moving. You may still get hit in the face, but at least the chain is no longer moving.

Testing Your Chain Brake

I’ll explain how to test your chain brake right here, but sometimes it’s easier to understand by watching a video. For that, I’ve found a great YouTube video from “Steve’s Small Engine Saloon.” Steve is full of knowledge and helpful advice; in this video, he shows you how to test your chain brake.

As you can see, your chain brake should easily activate by pressing down/forward on the chain brake hand guard. It’s meant to be activated by your forearm in the event that kickback occurs.

You can perform this test simply by pushing the chain brake hand guard with your hand. It shouldn’t be too difficult to activate. Steve has another way of testing the chain brake, which is best explained by watching the video.

Low-Kickback Chain

Low-kickback chains are sometimes called “Anti-Kickback Chains,” but that name isn’t quite accurate; kickbacks can still occur while using them. These chains are designed to reduce the forces which cause kickback.

They cut slower than a normal chain but, like the name implies, the chances of kickback or lower than that of a normal chain.

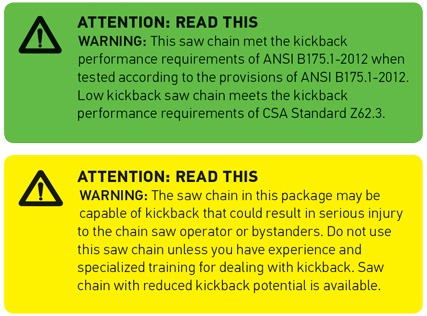

So, how do you tell whether or not the chain you’re buying is a low-kickback chain or not? The label. A green label indicates that the chain you’re purchasing has met the requirements.

On the other hand, a yellow warning label reveals the chain is not a low-kickback chain. You can see the warning labels below.

Bumper Spikes

Not every chainsaw comes with bumper spikes (called “buck spikes”). Some brands offer them separately, but that’s something you can check into later if you’re interested. Bumper spikes are mostly used in bucking.

When the opportunity presents itself, the bumper spikes can be used to rest the chainsaw against the wood you’re cutting. As you can imagine, you won’t be utilizing bumper spikes all the time – but they’re another means of helping to protect yourself from kickback.

Further Knowledge & Learning

One of the best ways to avoid kickback is knowing what causes it and understanding how it happens. By this point, you should have a general understanding of kickback.

Don’t stop here, though. I encourage you to do some more research on the subject. You can never be too safe when it comes to chainsaws.

To point you in the right direction, I’ve listed a few sources below where you can learn more about kickback and general chainsaw safety.

- How to Use a Chainsaw Safely (video) from the U.S. Agricultural Safety and Health Centers

- General safety tips from the University of Georgia

- General safety tips (video) from STIHL

I hope this guide has helped you get a better understanding of what chainsaw kickback is and what you can do to reduce the chances of it happening to you. Remember, no matter the level of training you receive on the subject, accidents happen from time to time. That’s why it’s important to wear all the necessary safety equipment, read the owner’s manuals, and be cautious.