How to Adjust Chainsaw Tension

Timber Gadgets is reader-supported. We may earn a commission if you buy through the links on our site.

To keep your chainsaw cutting with the most efficiency, you want to check the chain’s tension regularly. Within a few hours of use, the chain will heat and expand and eventually need readjusting.

Whether you’re new to chainsaws or you’ve never done this before, adjusting the tension for the first time can be confusing. Don’t worry; it’s not too fairly easy, and that’s precisely what this page is for.

Not all chainsaws are the same, but most of them are similar when it comes to this task; the biggest difference usually comes in the location of the chain tension screw.

I’ve provided a step-by-step guide below and found a very helpful video to give you the most information possible. Before we get into it, I’ll quickly review the “snap test.”

The snap test is simple yet effective means of testing the chain’s tension. This will help you determine whether or not you need to adjust the tension.

Table of Contents

Checking the Tension Using the “Snap Test”

The first step in this whole process is to determine if you need to adjust the tension to begin with. Most of the time this is obvious; a sagging chain is always a good indicator or perhaps you’re replacing the chain altogether. That’s not always the case, though. Sometimes it can be hard to tell without performing the “snap test.”

Before you perform a snap test, it’s a good idea to disconnect the chainsaw’s spark plug lead for safety purposes. Also, wearing some decent gloves is a good idea too. Once you’re ready, it’s time to perform the snap test.

Place one hand on the chainsaw to hold it still. Using the other hand, grasp the chain near the middle of the bar on the top side; use your thumb and index finger. Pull the chain up and away from the bar and release it.

If the tension is correct, the chain will snap back into place and show no signs of sagging. If the chain is sagging on the bottom or loosely falling back into position on the top, it needs to be tightened.

You can perform the same test on the bottom of the bar. When you pull the chain down, the drive links will be exposed. The drive links shouldn’t extend below the edge of the bar. In the picture above, you can see the drive links, and I barely pulled on the chain. Needless to say, it needs to be tightened.

Related:

Adjusting the Chain Tension

Once you’ve performed a snap test and you’re positive you need to adjust the tension, the step-by-step guide below should help you do so. The tools you’ll need for this project likely came with your chainsaw – a scrench (pictured below this paragraph).

It has a flat-tip screwdriver on one end and a socket on the other. If you don’t have the scrench, don’t worry. Just get out your socket set and a normal flat-tip screwdriver.

Step 1. Safety First

It goes without saying, but you certainly don’t want to tighten the tension while the chainsaw is running. I know that. You know that. I know you know that… but just in case, make sure the chainsaw is not running.

Many people suggest you remove the spark plug lead just to be sure. I also recommend doing this for safety purposes. While at it, slip on a nice pair of gloves and safety glasses for protection.

Step 2. Loosen the Clutch Cover Nuts

Using your socket set or scrench, loosen the clutch cover nuts. You don’t need to remove them completely. Gently loosen both of them. They’re located on the side of the chainsaw where the bar enters the motor cover. I’ve created a (not so fantastic) illustration to point out the most common locations of these parts.

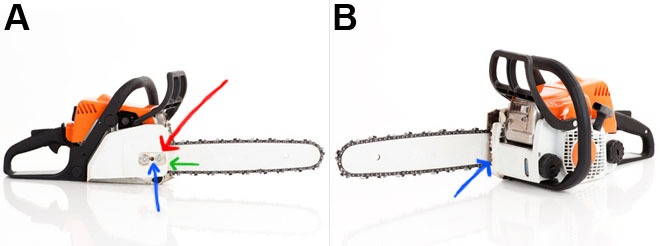

In illustration “A,” you can see two clutch cover nuts indicated by the red arrow.

Step 3. Hold the Bar Up & Adjust Chain Tensioning Screw

Once you’ve loosened the clutch cover nuts, it’s time to tighten the chain’s tension. You can do this by turning the tensioning screw clockwise. Depending on the brand of your chainsaw, the tension screw can be in a different location than the one in the illustration above.

Most of the time, you can find the tensioning screw where the blue arrows are pointing in the illustration above. Some brands have tensioning screws on the front part of the engine cover where the green arrow is pointing in illustration A.

If you’re unable to find it, I recommend reading the owner’s manual or searching google to find the location of the tensioning screw for your chainsaw’s brand and model.

Once you’ve found the tensioning screw, turn it clockwise while holding it up on the nose of the bar. By the way, if you’re not familiar with all these terms, I recommend reading this page about the parts of a chainsaw.

Step 4. Tighten the Clutch Cover Nuts & Check the Tension

Once you’ve finished tightening the chain, make sure you tighten the clutch cover nuts too. Now it’s time to check the tension again. Perform a snap test and turn the chain to ensure it isn’t too tight. When you rotate the chain, pull the chain towards you from the top of the bar. Go slow and be careful.

Pulling the chain in the opposite direction will likely result in you getting cut. Again, be careful. Having the chain too tight will increase friction and bog down the motor.

Having it too loose can cause the chain to come off the bar. Both of which are dangerous and may result in serious injury.

Step 5. Finish or Readjust the Tension if needed…

If you need to tighten the chain again, repeat steps 2 thru 4. Likewise, if you determine the chain is too tight, then you should loosen the chain.

I recommend watching the video below for more information. Once finished, ensure all the nuts are tightened, and your spark plug lead is reconnected.

Perform all the standard safety checks before starting and using the chainsaw. I’m not responsible for your safety and well-being. Please use common sense and consult your owner’s manual as needed.

In-depth Video Guide

I’ve watched a handful of videos searching for the one that best describes adjusting the chain’s tension. There are several very helpful videos, but this one is my favorite.

Sure, it’s nice to read a guide on how to do something, but watching in video format can be even more helpful.